Things you should definitely do when setting up a product line

I've been working a lot on Solo and setting up the supply chain for it. I set up a production run in China for USB models that went out to our Kickstarter backers. Then with the help of one of my teammates, Emanuele, we set up a new production run in Italy. This time more designed to be recurring small-batch runs, rather than one large batch. This certainly could have been done in China, but for tax and security concerns, we opted to move to somewhere in the EU.

The processes from running the Kickstarter campaign, to manufacturing, programming, testing, and finally shipping, all unfortunately required manual, tedious labor that could have been avoided. I'll share them here.

Management of your orders and customers

In an ideal situation, you will only have one product and there can be no variation to it. This means your customer can not indicate any preference for the type of product being purchased; there is only one. This makes it really easy to decide how your supply chain will look and how things will get packaged and delivered.

We, however, did not strive for this situation as best as we could have. For each key, we offered the choice of USB-A or USB-C. We offered two types of keys, NFC or USB-only. That's four different products so far.

We also offered the preference for people to get keys in an unlocked state. It's not secure, but is good for people that want to reprogram their keys and potentially contribute to the open source project, so we definitely wanted to support them.

But now we have eight products. And it's tricky to offer this on Kickstarter since it's not set up like a store. It's set up to have fixed pledges with fixed combinations and quantities. Customers can only pick one pledge.

And colors. We offered multiple colors. This certainly adds complexity, so we ended up just making packs of all the colors and giving them to everyone. It's another preference customers can indicate and we have to track. And with more choices given to the customer, the more risk for complaints when mistakes are made (by us or the customer).

Despite this complex product offering, we opted not to use a 3rd party survey tool meant to integrate with Kickstarter campaigns. It would make managing people's preferences much easier and allow them to buy multiple pledges. But it cost $2k + some % of the total funds raised, so we opted not to use it. Now looking back, it would have made managing everyone's preferences *much* easier. Kickstarter's built in survey tool is basic and lacking -- probably designed for simple product offerings intentionally.

For your product offering, you shouldn't be very involved in managing preferences of your customers. You should only be there to download the data to (1) make the manufacturing order and (2) send the data to the fulfillment company.

Fulfillment

Unless you're making a low volume amount of items (<500), you should be using a fulfillment company. There's a lot of them and it can be a consuming task to find the right one. But it will be no where near as consuming as if you do it yourself. You should do this before your campaign is live.

This means you should plan what your UPC-codes/barcodes are going to be, and tell your manufacturer to package your products and put barcodes on each product. Fulfillment companies will know how to turn your CSV of backer data, and barcoded items, into shipped products. It is probably going to be more expensive than you'd expect, but fulfillment is harder than it seems.

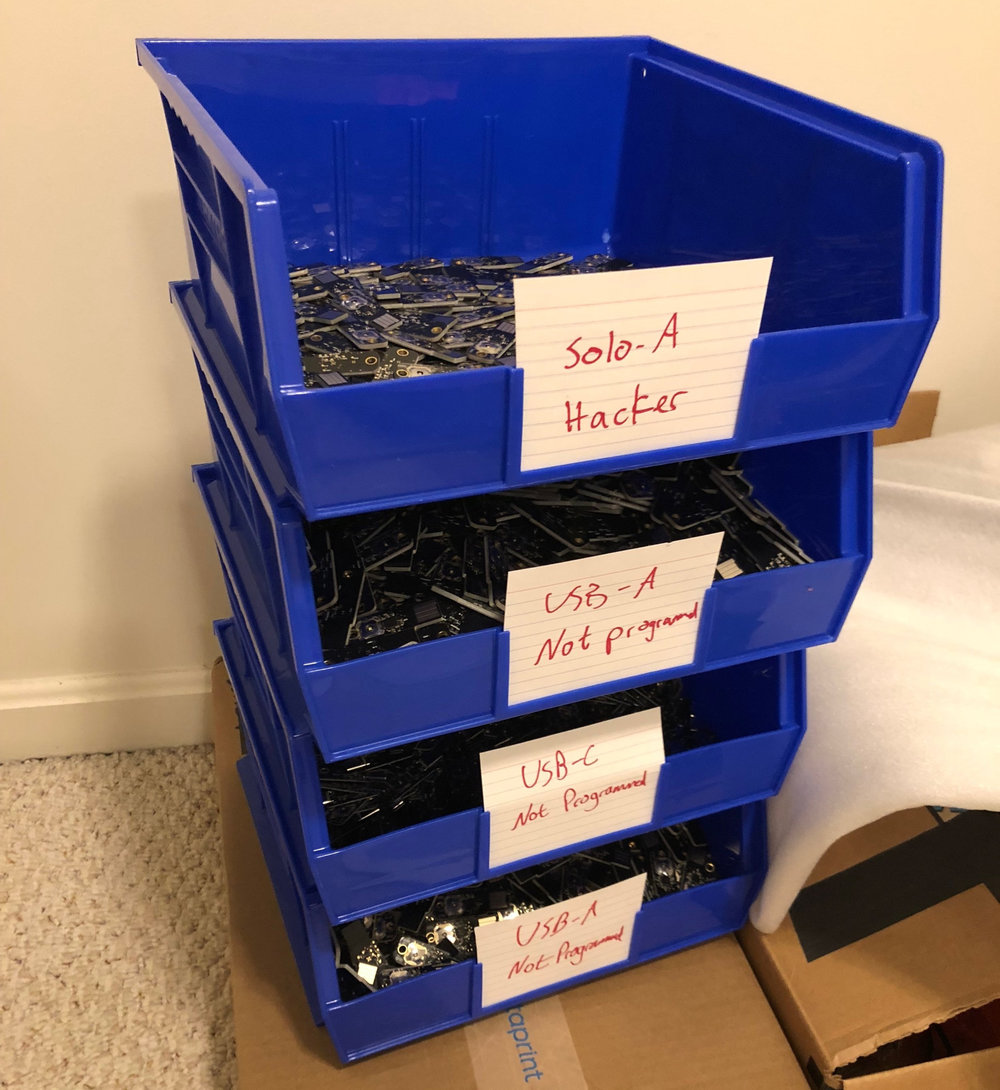

For Solo, we did not use a fulfillment company. We did not package our keys or put any barcodes on them. In fact, the initial batch of keys shipped unprogrammed and I manually programed them. This was done so there would be more time to improve the firmware before shipping, and so we can say the programming and testing was done in the US. But it caused me a lot of tedious labor. About 2-3 seasons worth of binge-watching Netflix while programming keys worth of tedious labor.

For shipping, it took multiple days with 4-5 people picking and packing various products to fulfill 1300 Kickstarter orders. We had to repeat the process again for a later manufacturing batch to fulfill our remaining 1500 orders.

Since this was done manually, inevitably there were a number of mistakes made in some peoples orders, that we had to correct over time. Not to mention ongoing support of people asking questions about their shipments. Shipping support is not something we need to be in the loop for -- this responsibility should be on the fulfillment company.

Whilst our campaign and fulfillment was going on I was still working full time as a computer engineer. I got pretty burnt out.

In retrospect it's quite obvious how we could have made our lives easier. At least we'll definite plan better for future ventures.

Maintaining distribution and inventory post KS

This pretty important for the future of the business or product line.

Suppose you make 1000 units, then you certainly have enough to fulfill 1000 orders.

What about the 1001st order? Will you be able to ship, or will you be out of stock and just starting a new manufacturing batch?

Maybe after selling 800 units, you'll be able to afford the next run, and it will be complete before that 101st order. It's a tricky balance to get right, but it should be considered. You don't want to have a successful product, and be forced into a long period of being out of stock. It may be totally worth taking out a inventory loan if needed to support post campaign sales.

Luckily we actually did think of this ahead of time and planned to order plenty of extra USB tokens using KS funds, and were able to set up distributors so we can keep the cash flow going. We did run out of USB-C tokens, and were unable to ship orders for them for 1-2 months.

When we set up our manufacturer in Italy, we included programming and packaging. Now we get shipments that are ready to sell and can be sent directly to fulfillment centers or distributors. No more manual programming, testing, or shipping on our end.

Take your estimated shipping time and multiply it by 3 and then add 5.

Just like the sage advice "under promise and over deliver".

Our shipment dates were a bit aggressive. Our KS campaign ended in August, and we planned to ship before Christmas for our USB models, and in February for our NFC models.

We wanted to be in time for Christmas to hit the gift appeal. And we actually did it. Most shipments went out by Dec. 20, and most U.S. shipments arrived before the 25th. International shipments mostly arrived in January.

For NFC, we were not so lucky, and had to delay 2 months due to technical challenges. Most of our backers understood, but it was still a setback for many people, and we were endlessly answering "Why hasn't my Tap arrived yet?", because you can't expect everyone to read the updates you send out. This certainly could have been alleviated with some more conservative time estimates on our end.

Be open and transparent

I tried to be as open and transparent as possible about everything we went through with our customers. We never got any negative response to any of our updates. We did get negative messages every once in a while, but these typically only happened when (a) we hadn't sent an update in a while, (b) a backer didn't get important tracking information about his or her order, or (c) we made a mistake with an order due to our manual processing.

For (b) we definitely could have been more diligent with our email campaigns, like checking read receipts and sending follow ups.

Success?

After this long, challenging process, we shipped quality, functional products to all of our backers. So despite some mistakes and hurdles, it was a successful and we are continuing to produce Solo and work on feature updates. We’re planning another crowdfunding campaign for Somu!

I am missing other mistakes with made? Probably.

Want feedback your product launch or crowdfunding campaign? Hit me up!

Digital discoveries

- Non Gamstop Casino Sites

- Non Gamstop Casinos

- Casinos Not On Gamstop

- Non Gamstop Casinos

- Non Gamstop Casinos

- New Betting Sites UK

- Non Gamstop Casino

- UK Online Casinos Not On Gamstop

- Casino Sites Not On Gamstop

- Best Non Gamstop Casinos

- Casino En Ligne France

- オンラインカジノ 一覧

- UK Online Casinos Not On Gamstop

- Sites Not On Gamstop

- UK Casino Not On Gamstop

- Best Non Gamstop Casinos

- Casino Non Aams

- UK Casino Sites Not On Gamstop

- Gambling Sites Not On Gamstop

- Non Gamstop Casinos

- Online Casino Zonder Cruks

- Non Gamstop Casino

- Casino Non Aams

- Casino Sites UK Not On Gamstop

- Casino En Ligne Crypto

- Paris En Ligne Belgique

- Tous Les Sites De Paris Sportifs Belgique

- Casino Belgique En Ligne

- Casino En Ligne

- Casino Italiani Non Aams

- Casino En Ligne France

- Meilleur Casino En Ligne France

- Casino En Ligne 2026

- Nouveau Casino En Ligne Francais

- Casino Senza Documenti

- Meilleur Casino En Ligne France

- Siti Non Aams Legali In Italia

- Casino En Ligne Français